About

Our history

The story of the company starts in 1982 when Anne-Marie Stevens and

Christian Vanvaek founded ISFI SA – in Braine-l’Alleud, near Brussels. What started as a local family business, turned into the biggest Belgian manufacturer of Herbs & Spices, exporting products all over the world.

In 2014, ISFI SA was acquired by a management team with a vast experience in FMCG and food. One year later, ISFI becomes the owner of the Piet Huysentruyt brand, covering a wide range of seasonings and adding bouillons to the standard assortment. In parallel, the new team succeeds year after year to enlarge the customer base of retailers, developing the herbs & spices category at high service levels. Over the past years, our foodservice channel has shown a steady growth, resulting in more and more professional chefs choosing the “ISFI” quality.

Despite the growth, ISFI has been able to keep the most important traits of a successful family business. We believe that loyalty, flexibility, cherishing genuine customer relationships and a true passion for herbs and spices make the difference for our customers. We are proud of our no-nonsense, creative approach which allows a fast implementation of customized product and category solutions.

As part of the company’s international growth, the management team has decided to give ISFI a new name that more accurately reflects what the company stands for and what exactly it does. In Februar 2023, The Spice Factory was born!

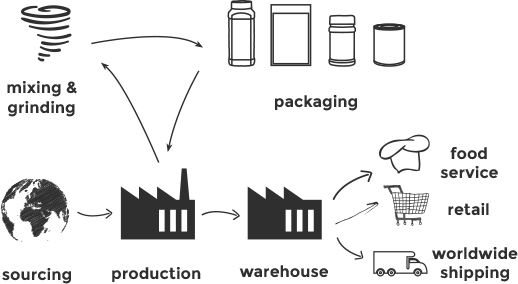

Our activities

Sustainability

ORGANIZATION AND PEOPLE

To achieve “The Spice Factory” vision, 5 core values are imbedded in our day-to day activities, in all parts of the organization: Passion, Efficieny, Accountability, Creativity and Empathy. The most valuable asset is our 100 employees. Their knowledge, expertise and passion for herbs and spices are essential to ensure a sustainable business growth. At The Spice Factory we feel responsible for our employees and we strive to create a safe and healthy working environment where everybody is respected for their contribution.

Multicultural dimension

The Spice Factory global span in sourcing and customer supply is reflected in the organization. We encourage cultural diversity and an open mindset within our workforce.

Integration of a sheltered workshop

The Spice Factory has chosen to integrate a sheltered workshop in the production environment. What started as an experiment, turned into a real corporate social mission. A team of 5 disadvantaged people executing specific tasks are participating within our standard working environment and are fully integrated in our workforce.

Communication

The Spice Factory favors transparent communication towards staff members with regards to objectives as well as on the results obtained. Operational KPI’s are defined in close collaboration between operators and managers. As a result, each team member is encouraged to take up responsibility for his or her working area. The operational teams of each production line discuss the defined KPI’s on a regular basis which enables continuous improvements where necessary. Direct input from people at the production line immediate actions implemented by the teams, close follow up and short communication lines lead to an efficient and flexible production environment while boosting individual engagement.

Working environment

The Spice Factory wants to provide a stimulating, productive and safe working environment to all of its employees. One of the most important focus areas has been our employee safety within the workplace. Making people aware of the existing protocols and providing specific safety trainings on a regular basis, ensures a safe working environment for each employee. Aiming to minimize any inconvenience in the production area, we invested in new dosing machines that are significantly less noisy. Also dust has been drastically reduced thanks to a new central vacuum system which can handle high loads. Furthermore, a range of personal protective equipment has been provided to our staff members.

Sourcing and supplier management

The Spice Factory ensures a total traceability from field to fork, with a strong focus on its sourcing policy. It has become essential to collaborate closely with local sourcing partners to develop a sustainable business. Quite a challenge within the industry of herbs and spices, since our sourcing partners are located all over the world and have their own regional habits of working. Nevertheless, within our sourcing areas there is a growing awareness of the global sustainability needs.

75% of the total volume of raw material is sourced directly in the country of origin. This gives us the opportunity to create local awareness on the importance of a sustainable approach. And more importantly, it allows us to collaborate with our local suppliers and help them overcome their day-to-day hurdles. Challenges as labor conditions, child labor, human rights, good agricultural practices, overuse of chemicals and pesticides, waste management etc. need to be addressed locally. The Spice Factory supplier base mainly consists out of small-sized farmers who rely on traditional methods to harvest premium quality products. It will always be a challenge finding the balance between local agricultural methods and cultural dynamics, and the requirement to source sustainably.

Therefore The Spice Factory participates in the BSCI program.

BSCI (Business Social Compliance Initiative) has become an important pillar of our supplier development plan. The Spice Factory supports actively the BSCI initiative and influences all its suppliers to implement this standard with their farmers. BSCI defines specifically high risk zones and the result of our work is encouraging: 70% of our suppliers are committed to BSCI standards or equivalents like Sedex. The Spice Factory puts realistic targets: we aim to have 85% on board by 2020.

BSCI (Business Social Compliance Initiative) has become an important pillar of our supplier development plan. The Spice Factory supports actively the BSCI initiative and influences all its suppliers to implement this standard with their farmers. BSCI defines specifically high risk zones and the result of our work is encouraging: 70% of our suppliers are committed to BSCI standards or equivalents like Sedex. The Spice Factory puts realistic targets: we aim to have 85% on board by 2020.

ENERGY, WASTE MANAGEMENT AND CO²

Next to sustainable development work with our supplier base, The Spice Factory takes the necessary actions to improve sustainability within the own organization. Areas of importance are energy, waste management and reduction of CO2 through supply chain initiatives.

Energy

Overall, the direct impacts of The Spice Factory as a production facility are limited: grinding, sieving, mixing and packing of herbs and spices is a low energy process. Nevertheless, different initiatives are taken to further reduce the consumption of energy.

Implementing preventive and predictive maintenance plans (including Infra-Red controls of the electric appliances) ensure the sustainable use of technical equipment and as such reduce the energy consumption on a longer term.

Another initiative is the gradual replacement of traditional types of lighting in offices and production facilities by LED-technology to reduce energy consumption and lower human intervention in terms of maintenance.

This type of initiatives is exemplary of The Spice Factory ongoing focus and pragmatic approach to reduce energy consumption.

Waste management

Maximal reduction of the different waste flows is another important priority for the The Spice Factory team. The installation of highly accurate dosing machines in the production facility has directly resulted in the reduction of raw material waste. For The Spice Factory, the reduction of packaging material is an essential part of the waste management program.

With our packaging suppliers, extensive work has been undertaken to considerably reduce the weight of bottles and caps. As a result, The Spice Factory can offer high quality lightweight packaging material while guaranteeing the freshness, flavour and taste of our products.

Close collaboration with our customers enables us to redesign secondary packaging to optimise consumer sale units with a direct impact on efficiency of palletisation. Cardboard consumption is reduced, warehouse pallet places are optimized and transport to our customers is more efficiently organized.

The packaging materials used in our facilities (glass, PET, PP, plastic film) are nearly 100% recyclable. Remaining waste such as paper, cardboard, Styrofoam and glass are reduced to the utmost. Where possible, materials are re-used within our facilities. For example, carton used on entering pallets with raw materials, are re-used in the palletisation of finished products. Collaboration with specific organisations such as Fost Plus, Valipac and Valorlux (Luxembourg), keeps our focus on continuous improvement of packaging and environmental impact.

Supply Chain initiatives

The Spice Factory has installed a partnership with a local logistic partner known for its proactive approach in terms of sustainability. They use 50% of EURO5 trucks and 50% EURO6 already. They are experts in grouping management so that the total carbon footprint is reduced.

Moreover, we encourage our customers to integrate our supply chains in order to reduce our carbon footprint. Key ideas are around maximisation of full truck load, full pallets or pallet layers deliveries. This supply chain integration is also developed with our key suppliers.

THE CONSUMER

The Spice Factory main goal is to achieve consumer satisfaction through delivering innovative concepts and providing high quality products at an impeccable service level. We simply want to be the best partner in offering herb and spice solutions for private brands and food service customers. The Spice Factory combines its expertise and passion for herbs and spices with a dynamic and flexible approach, resulting in authentic customer relationships and more importantly, happy consumers! Consumers’ demands are important for The Spice Factory, and we are continuously looking for opportunities to meet these needs in a tasty, innovative, healthy and sustainable way.

Allergen management

Allergen management is becoming more and more important for the consumers nowadays. To avoid cross-contamination, The Spice Factory applies strict measurements in terms of production planning and cleaning when raw materials such as sesame, celery, mustard, milk, gluten and soya enter the production facility.